What you should know about modified plastics

In production, we find that more and more products use modified plastics as materials ,particularly in the the automotive and home appliance industries. Benefit from the use of modified plastics,the two industries have achieved "lightening of automobiles and thinning of home appliances". So,I have the question that why does modified plastics have so much energy? First we look at the history of plastics.

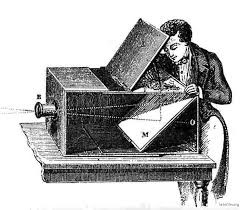

After searching the data, I learned that the first plastic was invented by a photographer in the dark room accidentally. One day in the 1850s, photographer Parkes tried to mix cotton with camphor. Surprisingly, a hard, flexible material was produced after mixing. Parkes called the substance "Paxin", and that was the earliest plastic. Unfortunately, the plastic market was not opened at that time. By 1868, the printer in New York, John Wesley Hayat, discovered the opportunity for a shortage of ivory. He improved the manufacturing process of "Paxin" and gave it a new name-"Celluloid" (false Ivory). After this, plastic products began to be commercialized, and soon more and more plastic products appeared on the market.

Since the development of plastics, thousands of polymer materials have been synthesized, but only five resins (PE, PP, PVC, PS, ABS) are commonly used. It is very difficult to continue to synthesize a large number of new polymer materials.Therefore, it is necessary to modify existing plastics.

In my understanding,modification means that the plastic changes its own characteristics through the modifiers strengthen advantages and avoid weaknesses, to expand the scope of application.In other words,modification is a measure to meet the production requirements of product by change the characteristics of the basic properties of plastics.The development of modified plastics is already becoming a major trend. Looking forward to the future development prospects of modified plastics, there will be three major changes.

1.General thermoplastic resins will continue seize some of the traditional engineering plastics application markets through modification.

2.Cost will be reduced in engineering plastics

3.High-performance engineering plastics will have increasingly important applications in cutting-edge technological fields such as aerospace.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds