Why do we need to proceed with the mold trial after the completion of the injection mold?

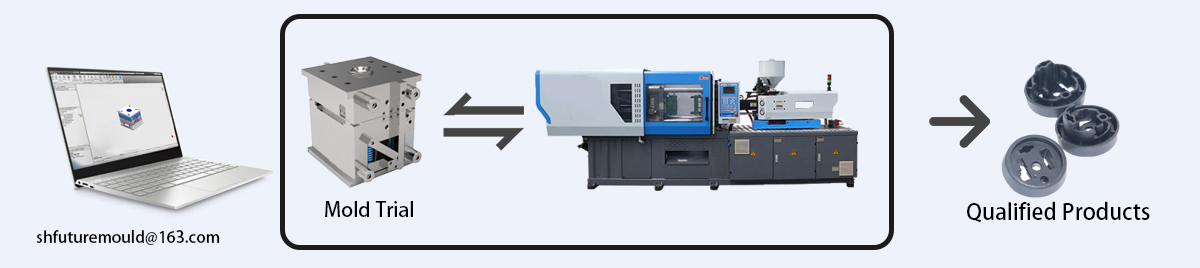

In the process of injection mold production, it is easy to know why we need to do mold trials. As we all know, the defects of molded parts are caused by material plasticization and injection molding, and improper mold structure design. The current factors that may affect product quality include the design of hot and cold runners, the location, size of the gate, etc. To avoid product defects caused by mold design, we need to test the mold before delivery and further analyze the mold design and mold parameters.

Before the mold trail, it is necessary to ensure that the injection molding machine can work normally, and adjust the parameters of the injection molding machine to make it fit for the corresponding material. The purpose of this step is to eliminate unstable factors other than the mold and to determine whether the mold meets the requirements of the clients by the actual performance of the plastic parts in the subsequent molding process. If there are obvious molding defects on the samples, the engineers need to analyze the defects and modify the mold structure to improve it. After completion of the mold maintenance, continue to do the mold trial. If the sample has no obvious defects, we can send the samples to our clients for confirmation. With the approval of our customers on the quality of the samples, we can proceed the delivery.

At present, with the continuous development of computer simulation technology, we can analyze the mold structure design in advance through the mold flow software. With the support of the mold flow software, we could adjust the mold design to eliminate the possible faults, which can greatly shorten the processing cycle of the injection mold production and save costs.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds