Why is it important to maintain the uniform thickness of the plastic molded parts?

Maintaining the uniformity of the wall thickness of the plastic part is an important measure of improving the appearance and quality of the plastic part, and why is uniform thickness so important?

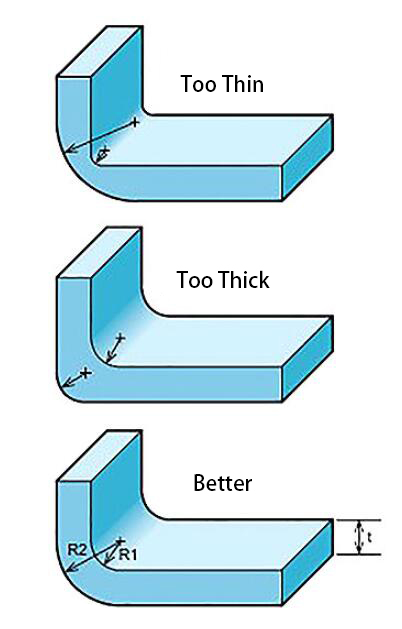

1. Uniform wall thickness can avoid sink marks on the surface of plastic products. The main reason for sink marks includes uneven wall thickness and unreasonable cooling time. If the wall thickness of the injection product is too thick, we can adjust the wall thickness or reduce the material on a condition that does not influence the product structure.

2. Uniform wall thickness can save more material in the project. At present, the prices of plastic materials worldwide are continuously rising, and designing a reasonable wall thickness can effectively save the loss in injection molding.

3. Uniform wall thickness can improve the spare utilization of the product, especially for the case product.

Maintain the uniformity of the product wall thickness is an effective way to ensure the appearance and quality of the product, what methods should we take to achieve it?

In the product design, set a reasonable product wall thickness according to the actual needs of the product is imperative.

If the wall thickness of the product is large, we can adjust it appropriately. For the area that needs to be removed, we can also set some ribs to make sure that the product structure is still strong.

Before we start the project, we can work with the mold supplier and design company to set this issue down at the beginning of the project.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds