Why is it tough to manufacture plug connector molds?

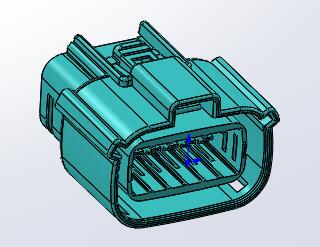

Connectors are imperative components in the automotive industry and electrical industry which requires high precision and insulation performance. On the one hand, the plug connector should protect the electrical safety of the products, on the other hand, it should be convenient in disassembly.

In production, the vital thing is the manufacturing of the molds. To meet the functional needs of the plug connector, we need to work cautiously in mold design and manufacturing. The following four tips in the connector projects, please check as a reference.

Higher mold design ability. The structure of the connector is diverse, so it must have a suitable mold design to ensure the precision of the plug connector.

Rich experience is required.

High-precision equipment. As a precision part, high-precision equipment is indispensable. For instance, advanced CNC machines, WEDM-LS, machining center, etc. This equipment is essential in mold manufacturing.

Molding equipment. In the molding stage, we need professional machine operators and injection molding machines as the foundation of mass production to ensure the stable quality of the plug connectors.

Shanghai Future Mould is a professional mold manufacturer based in Shanghai, our company has many years of experience in plug connector mold and product design and manufacture. We have designed and processed different types of connectors for many world-class companies. Welcome to contact us for further communications.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds