Injection Mold

Mould Manufacture

FutureMold is an industry-leading custom plastic manufacturer serving customers worldwide. Annually we build hundreds of injection molds for customers range from first-time inventors all the way up to Fortune 500 companies. The precision can reach a high range of ±0.01mm for molds and ±0.02 for plastic molding parts.

Over time FutureMold has become known for our ability to injection mold very complex components with a high precision and final appearance. We accomplish this through our advanced mold design department staffed with industry veterans who both understand the needs of injection molding as well as our proud moldmaking system. Complex ribbing, numerous undercuts, overmolding, insert molding, internal and external threads are all commonly present in our molds. Likewise, if our customers request a higher production rate we will build multi-cavity and fully automated tooling to meet these requirements as needed.

With all those rich experience, we're always offering an extremely efficient process resulting in delivery of injection molded components at a very competitive price.

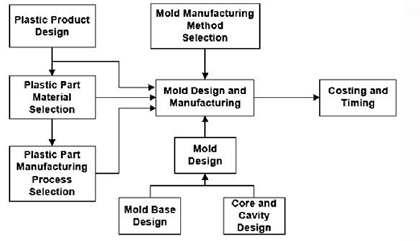

In this section, we'll show you factors affecting the cost of an injection mold to help better confirming your needs.

Factors affecting the injection mold tool cost:

Tool Material

Custom injection molds sometimes can be very expensive to manufacture, and one of the key point is the tool material selection. A simple fact is that the price of high-end steel can be dozens of times that of ordinary steel, and steel will cost more than double comparing with aluminum. This is due to the much slower machining process required for steel, and the slower manual benching process to complete the molds prior to molding. High volume projects (millions of components) normally require tool steel due to its wear resistance, which also explains why higher price molds will cost more production period.

But this does not mean that steel is always better. Given the advancements made in aluminum alloys, higher grade aluminum such as QC-7, QC-10 or aircraft grade aluminum close the gap between the durability of steel and aluminum while retaining the cost and machinability advantages of aluminum. Today, aluminum molds can produce hundreds of thousands of parts and maintain accuracy and surface finish. In addition, when molded parts require highly abrasive materials, aluminum tools can be coated or engineered with steel inserts for high wear areas of the tool.

When it comes to the molding process itself, aluminum tools can offer faster molding cycles due to better heat dissipation for cooling, reducing the longest portion of the molding cycle. Shorter cycle times equate to lower piece part prices.

· Cavity– Annual volumes will decide the cavity number for molds. Generally a multy-cavity mold will cost times of that for one cavity mold. Meanwhile, the additional cost of these tools will be offset by higher productivity and the lower unit product price. Our term is to help to figure out the best mold solution for you, and our quotes will commonly include several choices for you to decide.

· Undercuts– Although we can use various techs to avoid undercuts, these will make the mold more complex and with higher cost. So sometimes, if no specific need for appearance, our engineering team will evaluate and offer you with a most economic solution.

· Inserts and Overmolds– Insert injection molding is the process of forming a plastic part around a different type of material, can be metal or just another plastic. This is typically done with simple metal objects like a nut or threaded rod. It's a daily work for FutureMold, not to mention dozens of sensor molds we've made for BOSCH for over 10 years. It is important to discuss the project objectives with our sales engineers to assure we consider the needs of the final application, whether prototype or production, when producing parts with these features to minimize cost implications, particularly if larger volumes will be required.

· Surface Finish– FutureMold offers various kinds of surfaces finishes from mirror polishing to fine textures. Generally speaking the finer the finish the more expensive due to the additional labor and time involved to achieve best possible finishes, but the fine finishes are all worth it. And texture is also a good way to cover the mighty defects for some special designs.

· Part Complexity– Part complexity can drastically increase the cost of a tool. The more faces or surfaces in the CAD model has, the higher the cost.