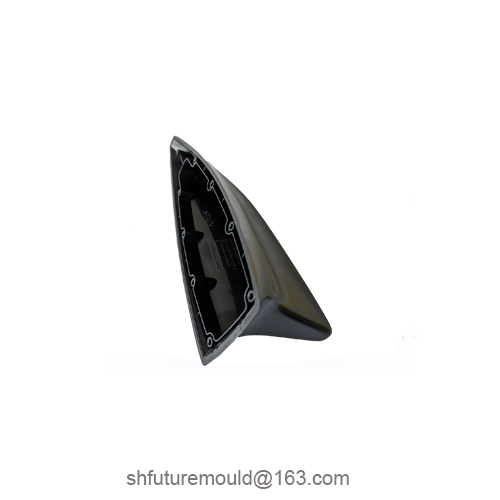

Automotive shark fin antenna mold

- Customized

- Customized

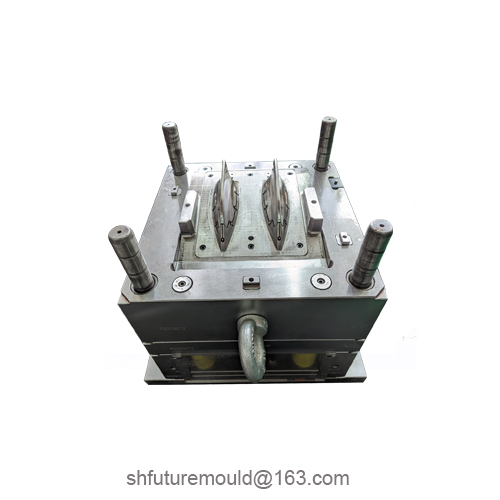

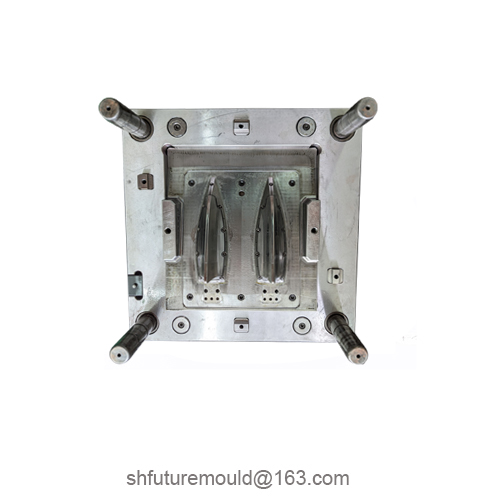

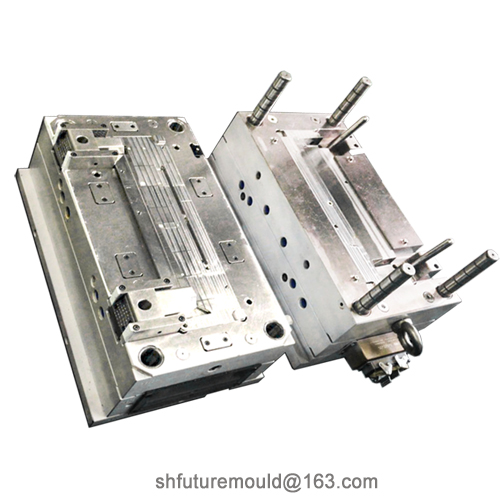

- Available(Mold&Product Design,Mold Manufacture) Technique Injection Molding/Insert Molding

- Injection Molding/Insert Molding

- Customized(Product Assembly,Complete Packaging and Bulk) One-Stop Service

- Credit Card,TT,(FOB)

We have a professional mold design team and experienced processing workers, and we can customize shark fin antennas and other automotive spare parts mold according to customer needs.

Automotive shark fin antennas have become increasingly popular due to their beautiful appearance and powerful functions. They can not only enhance the signal reception capacity of cars but also reduce the wind resistance coefficient and improve the overall appearance design of cars.

Functions of an automotive shark fin antenna:

Signal reception. The main function of the shark fin antenna is to receive and amplify signals from radio stations, satellite navigation systems, and mobile base stations, providing better signal quality for car entertainment systems, and navigation systems.

Reduce wind resistance. The streamlined design of the shark fin antenna can effectively reduce wind resistance, improve the fuel efficiency and handling stability of the vehicle, and reduce the driving noise of the car.

Static electricity release. The shark fin antenna has the characteristic of releasing static electricity, which can release the static electricity accumulated on the car body. This is crucial for protecting passenger safety and vehicle circuits. Especially in dry environments, static electricity can damage electronic devices and cause sparks.

Aesthetics. The shark fin antenna has a more stylish appearance, which can improve the overall appearance design of the vehicle.

Processing precautions for shark fin antenna mold:

Raw material selection. Shark fin antennas are usually made of engineering plastics such as PC. ABS, and PBT, require high-temperature resistance, corrosion resistance, and impact resistance.

Mold design. The shape of the shark fin antenna is complex, and the processing accuracy of the mold is high, it is necessary to consider the draft angle, parting surface design, and gating system design.

Processing technology. The surface of the shark fin antenna is smooth, and high-precision processing equipment and technology are needed to avoid burrs, air holes, and other defects.

Our advantages:

We have a professional mold design team and experienced processing workers, and we can customize shark fin antennas and other automotive spare parts mold according to customer needs.

We have advanced mold processing equipment and a perfect quality control system to ensure mold processing accuracy and product quality.

We provide a full range of services, including mold design, processing, mold testing, and mass production, to meet the diverse needs of customers.