How to define the short-run mold?

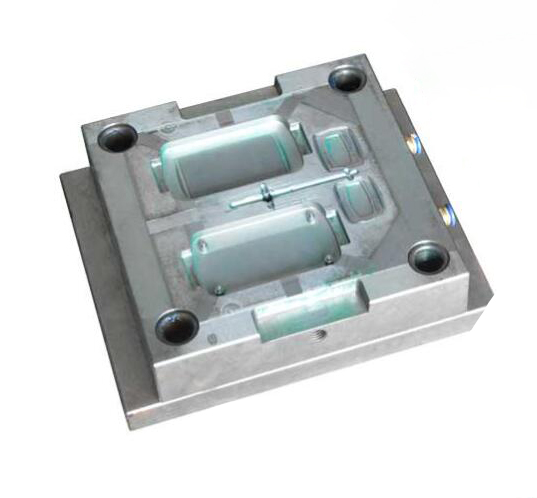

Before a new project starts, the product structure and function need to be verified by 3D printing or vacuum forming, and do we have other methods to check the product structures? Short-run mold will be the best option at current. The design and processing of short-run molds are the same as the standard molds, the target is to double-check the product structure and function.

Short-run mold is different from standard molds in terms of molding principle, mold structure, mold material, etc. Also short-run molds have a short design and manufacturing cycle, low cost, and have proper product quality, and now the short-run molds become the first choice for product verifications.

Short-run molds adopt simple mold based to replace standard bases, and please note that if the product size is overlarge, there has no suitable simple mold bases. The product cavity can also be curved on the mold base directly, and the mold structure is simpler than the standards. The steel used in short-run mold normally has poor performance on strength and rigidity, and is not suitable for long-term molding. If the structure testing is far beyond your target, standard molds manufacturing for mass production will be always our first recommendation.

Shanghai Future Mould is a professional injection mold manufacturer, and our company can provide customers with short-run mold manufacturing services, and at the same time, we can assist customers to analyze the structure and function in the design stage, and fasten the project.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds