PEEK molding

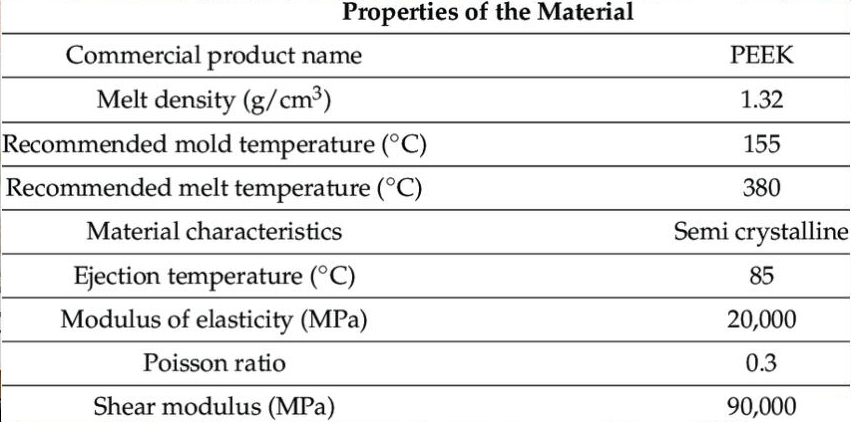

PEEK injection molding is a process of creating parts from PEEK (polyether ether ketone), a high-performance thermoplastic. PEEK is known for its strength, stiffness, chemical resistance, and biocompatibility, making it ideal for a wide range of applications, including medical devices, aerospace components, and industrial equipment.

PEEK injection molding offers a number of advantages over other manufacturing processes. PEEK parts are strong, lightweight, and resistant to a wide range of chemicals and environments. They are also biocompatible, making them ideal for medical applications.

Here are some of the industries that PEEK suits:

Medical devices: PEEK is used to create medical devices such as implants, surgical instruments, and catheters.

Aerospace components: PEEK is used to create aerospace components such as engine parts, landing gear, and structural components.

Industrial equipment: PEEK is used to create industrial equipment such as gears, bearings, and pumps.

Other applications: PEEK is also used in a variety of other applications, such as automotive parts, electronics, and consumer goods.

If you are looking for a high-performance material that can be used to create a wide variety of parts for a variety of industries, PEEK injection molding is a good option to consider.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds