Some guidelines for determining the appropriate draft angle

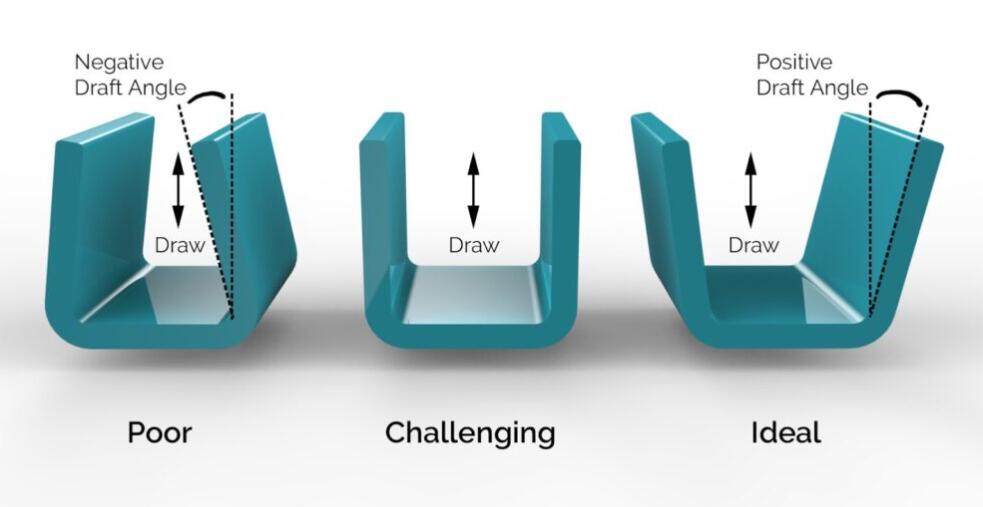

A draft angle is the angle applied to the vertical wall of an injection molded parts to assist with releasing the part from the mold. Draft angles are a required feature of injection-molded custom parts, because, as the molten plastic flows into the closed mold cavity and fills the cavity, the draft angle provides a taper that allows the part to be easily removed from the mold.

Here are some guidelines for determining the appropriate draft angle for your part:

1. Material: some material, such as ABS, shrink more that others. This means that you will need to add a larger draft angle to parts made from these materials.

2. Wall thickness. Thinner walls require a larger draft angle than thicker walls, because thinner walls are more likely to warp or curl when they are removed from the mold.

3. Surface texture: Parts with a textured surface require a large angle than parts with a smooth surface. This is because the texture can create areas where the part is more likely to stick to the mold.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds