The classification and structure of the injection mould base

The mold base is a part of the injection mold, and it is mainly used to support the molding mechanism in the mold, at the same time, the mold can be fixed to the injection machine for further production. In other words, the mold base plays as a connection part to the mold and the injection machine.

In the production process of the mold base, it can be divided into a standard mold base and full-process mold base by the actual processing requirements. The standard mod base is a mold base that is processed to improve production efficiency. The mold maker can perform secondary processing on the standard mold base according to the actual needs, and replace the matching mold cores and accessories. The standard mold base can greatly improve mold production, and shorten the production cycle. The full-process mold base is more convenient to use, but relatively speaking, the cost is also high.

As an integral of the finished mold, the mold base materials and processing techniques are the main factors that affect the actual service life of the mold, and before the production, it is necessary to have a clear understanding of the required accessories standard and tolerance requirements. If there is no special requirement for the material of the mold base, normally, the standard S50C is adopted as the raw material of the mold base.

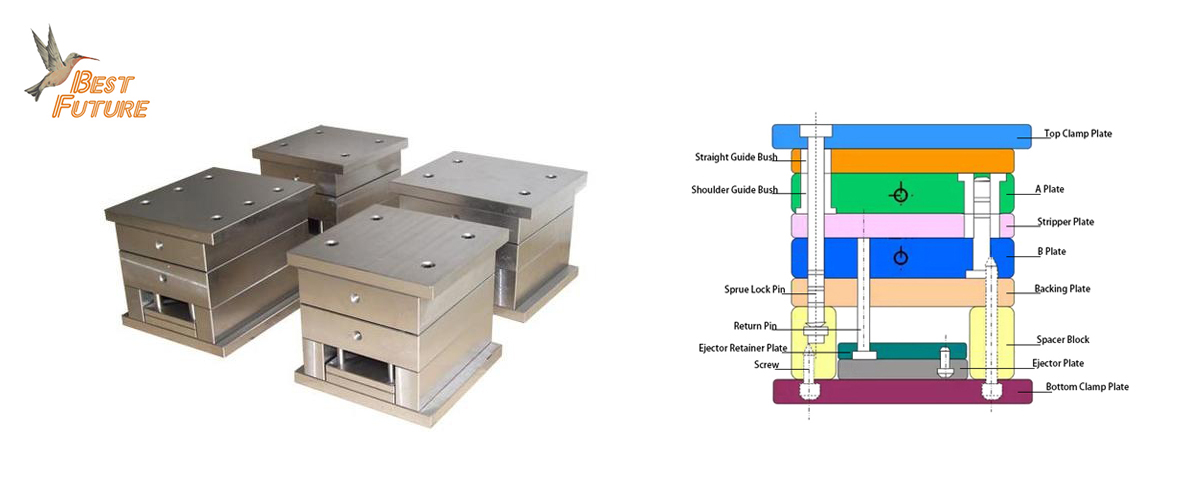

The structure of the mold base can be divided into the panel, A plate, B plate, bottom plate, guide pin, return pin, and other parts. It is combined with the mold core to form a complete mold. In the selection of the mold base, the mold base and related accessories can be adjusted by the actual size of the injection parts, and by the complexity of the injection parts and the design plan of the mold, to produce the most suitable mold.

The injection mold is an industrial production tool with higher precision and higher complexity. The auxiliary parts and tools of the internal molding parts are attached to the mold base, which requires high accuracy in the processing of the mold base. In general processing, 3D drawings are the most accurate, and the structure of the mold base at a specific location can be clearly understood. The accuracy of 2D drawings in most cases is not as clear as 3D drawings, and the probability of mistakes in post-production is higher.

The mold base industry and the injection mold industry are complementary. At present, the mold base products have a high degree of maturity and can be produced quickly according to the requirements of the mold manufacturers.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds