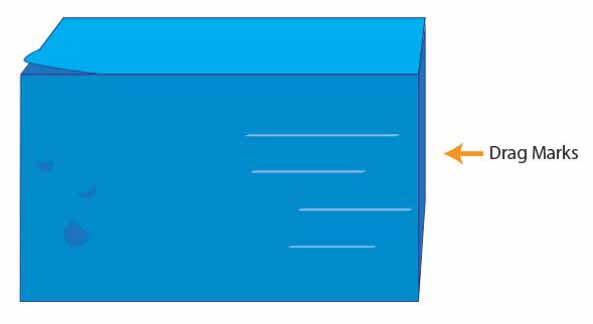

The drag mark of molded parts and how to prevent it?

The drag mark on injection molded products has always been a fatal problem for the product with high appearance requirements. Except for mold design and mold manufacturing, what aspects should be paid attention to in the molding process?

1. Excessive injection pressure

The excessive injection pressure will cause the product to be too full in the cavity and produce drag marks.

The excessive injection pressure will cause internal stress on the plastic parts, thereby causing deformation. If the deformation position is inside the cavity, the product will have flaws after demolding.

The excessive pressure will cause the product to have no shrinkage spare for cooling, making the product stick to the cavity.

2. Temperature

To achieve the special requirements of plastic parts in molding production, it is necessary to heat the mold, which makes the fluidity of the melt material stronger, and the cooling time will be longer. If the injection pressure is not adjusted in time when the temperature rises, the injection pressure will be too high, and the product will see drag marks when it is released from the mold.

After properly adjusting the mold temperature, the pressure needs to be adjusted to ensure the injection quality and to prevent the defects brought by the adjustment of the molding machine on the quality.

3. Impurities

After long period of molding, the impurities such as iron chips, dust, will enter the mold cavity to cause quality issue on the molded parts. Mold maintenance and cleaning should be carried out regularly to ensure the good condition of the mold.

4. Clamping force

The clamping force of the injection molding machine should be set according to the actual needs of the mold, which can prolong the service life of the mold, and reduce energy consumption, and can avoid quality issues due to the large clamping force.

After the flaws appear on the molded products, we must analyze the reasons in time and make adjustments according to the actual conditions. The above methods you can take as reference. If you have unsolved mold defects, welcome to contact us for help.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds