What are the main technical parameters of the injection molding machine?

The main technical parameters of the injection molding machine are as follows:

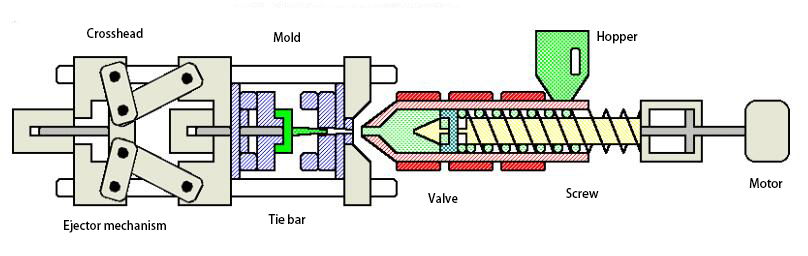

1. injection volume: refers to the maximum amount of molten plastic injected by the device when the screw makes a maximum stroke.

2. Injection pressure(MPa): The pressure required by the injection molding machine to inject molten plastic into the mold.

3. Injection time: refers to the shortest time that the screw can achieve the maximum injection volume once.

4. Injection speed: the maximum speed at which the screw moves during the injection.

5. Screw diameter: the outer diameter of the screw.

6. screw speed: the minimum and maximum speed of the screw when the material is plasticized.

7. Mold clamping force: it is the pressure that needs to be exerted when the movable mold and the fixed mold are tightly closed in the operation.

8. Mold installation size: The dimensions of the mold that can be installed on the molding machine.

9. Inner distance of the tie bar: the distance between the horizontal direction and the vertical direction of the inner side of the tie bar of the molding machine.

10. Ejection stroke: the maximum displacement distance when the ejector mechanism is ejected.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds