What issues should be noticed in ABS molding?

The molecular structure of ABS contains high-rigidity benzene rings and other structures. While improving the heat resistance of ABS material, it also leads to greater internal stress during the processing of ABS, which leads to quality problems such as cracking. Therefore, the internal stress of the product is an important issue in the injection molding process of ABS materials.

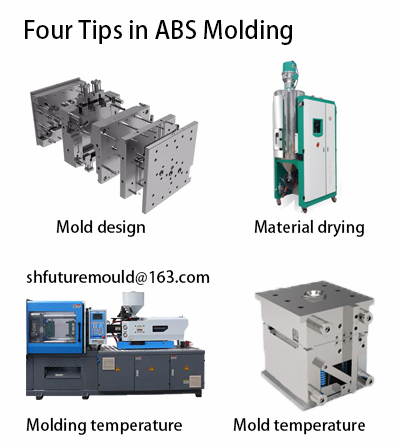

To improve product quality and reduce internal stress, we can improve the entire injection molding process through the following methods, they are:

1. Mold design

The product wall thickness is required to be uniform, and the difference of the product wall thickness should be controlled within 25% to prevent excessive wall thickness differences. In the design of the cooling water channel of the injection mold, the uniformity of cooling should be good to avoid uneven cooling and inconsistent shrinkage.

2. Drying of the raw material

ABS material will absorb moisture in the air during storage and delivery. Before injection molding, we should dry the raw material to ensure that the moisture content of the material is below 0.05%, otherwise, surface defects such as silver wires will appear. The drying temperature of ABS material can be set between 80-95 degrees, and generally takes about 3 hours.

3. Molding temperature

The mold temperature is a parameter that needs to be mentioned in the molding process of ABS materials. Try to set the molding temperature slightly higher than the recommended temperature by the supplier. Increasing the molding temperature can reduce the viscosity of the ABS material, increase its fluidity, and ensure the filling capacity of the material.

4. Mold temperature

During the injection molding process, we should set the mold temperature properly to ensure that the product has a reasonable molding cycle while avoiding defects such as internal stress.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds